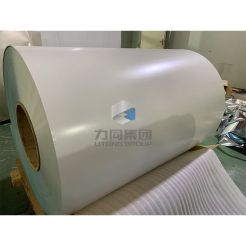

pvdf coating on aluminium

Product Description

https://www.alupaintcoil.com/aluminium-stripe-for-exterior-horizontal-blinds.html

Aluminium Stripe for Exterior Horizontal Blinds

PVDF Coating on Aluminium

PVDF (polyvinylidene fluoride) coating on aluminum is a process that involves applying a layer of PVDF resin to the surface of the aluminum through a series of steps, including cleaning, priming, and baking. The PVDF coating provides the aluminum with excellent weather resistance and durability, as well as good chemical resistance.

The process of applying PVDF coating typically begins with cleaning the aluminum surface to remove any dirt, oil, or other contaminants. The aluminum is then treated with a chemical solution to etch the surface and create a rough surface for the coating to adhere to. Next, a primer is applied to the aluminum to further enhance the adhesion of the PVDF coating.

The PVDF coating is then applied to the aluminum using a roller or a spray gun. The coated aluminum is then heated in an oven, where the coating is cured and hardened. This process is typically done at a high temperature of around 150-180°C to ensure a good curing of the coating.

PVDF coating provides excellent resistance to UV rays, extreme temperatures, and other environmental factors, making it a popular choice for exterior architectural and construction applications. Additionally, PVDF coated aluminum can be produced in a wide range of colors and finishes, providing architects and designers with a lot of flexibility in their designs.